8 Different Types of Binding Machines

Making final decisions when it comes to purchasing binding machines can be stressful. Even if it’s not a huge investment, you want to make sure you end up with a reliable piece of machinery that will get the job done and. Ideally, you won’t have to worry about replacing the binding machine anytime soon.

The best way to get started is to familiarize yourself with the different types of binding machines. Below is a list with eight different types of binding machines available, which you can then compare to your specific requirements.

1. Comb binding machines

Comb binding, which you might also see referred to as “cerlox or surelox binding,” is one of many ways to bind pages together into a book. This method uses round plastic spines with 19 or 21 rings and a hole puncher that makes rectangular holes. Comb binding machines punch round holes on the left side of the pages, and those pages are held together by a comb.

These types of binding machines are ideal for small and thin books. Comb binding machines work by opening and closing when the loose pages are to be inserted or removed. In general, comb binding machines can be supplied with either a manual or electric punch, but keep in mind that this method is considered to be the least flexible style of bookbinding due to the plastic spine that forms the back of the binding.

2. Coil binding machines

Also known as spiral coil machines, coil machines work by using a punch to create holes along the edge of the document. Then, a coil inserter spins the coils through the holes and finally, a pair of coil crimping pliers or a crimping machine is used to cut off the excess coil and crimp the end to prevent the coil from coming loose from the document.

These types of binding machines are largely considered to be preferable to the comb binding method. The machines punch holes to bind the pages with a continuous spiraling plastic coil. In most cases, the coil is made from PVC, which is both flexible and durable. Coil binding machines are perfect for binding notebooks and legal documents. It is also a good book binding machine for home use.

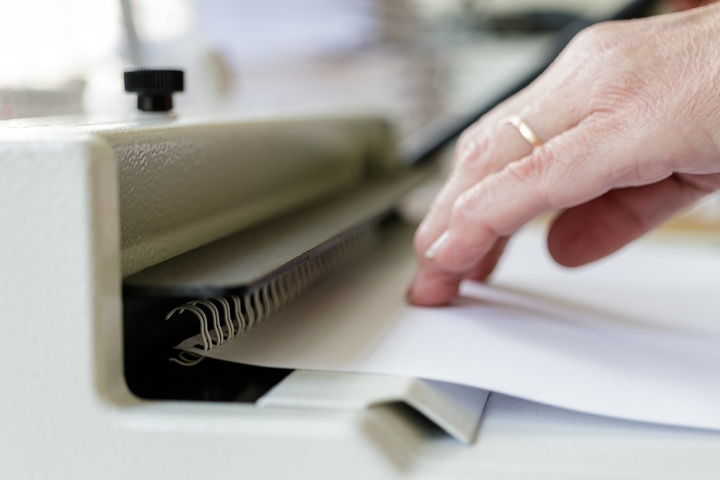

3. Wire binding machines

Wire binding is one of the best book binding methods. This technique is known by a number of different names, including twin loop wire, wire-o, double loop wire, double-o, ring wire and wirebind. Similar to other types of binding machines, wire binding machines also punch the holes in the pages and then uses multiple wires to bind the pages.

The machine then bends and closes the wires together onto a “C” shaped spine and, after the pages are holed and fed into the wire ring, squeeze the spine until it is round. This method of binding is considered the go-to choice for large books and documents, as well as those who want to design custom binders with personalization.

4. Thermal binding machines

As you might expect, thermal binding uses heat to bind the documents to the cover. Actually considered easier than many other types of binding, a thermal binding machine works a bit like a toaster, by heating the glue within the cover so that it quickly binds to the paper which has been inserted.

It’s a relatively quick way of binding documents, doesn’t require much effort, and ultimately provides a polished finish. For this reason, these types of binding machines are widely used for giving a professional look to documents such as manuscripts.

5. Tape binding machines

Tape machines are appealing because they can turn loose pages into a professionally bound book in a matter of seconds. These machines simply use a strip of adhesive tape to bind the edge of the pages together. They are straightforward to use and cost effective, ideal if you’re looking for a method to give a tidy, finished appearance to the loose documents.

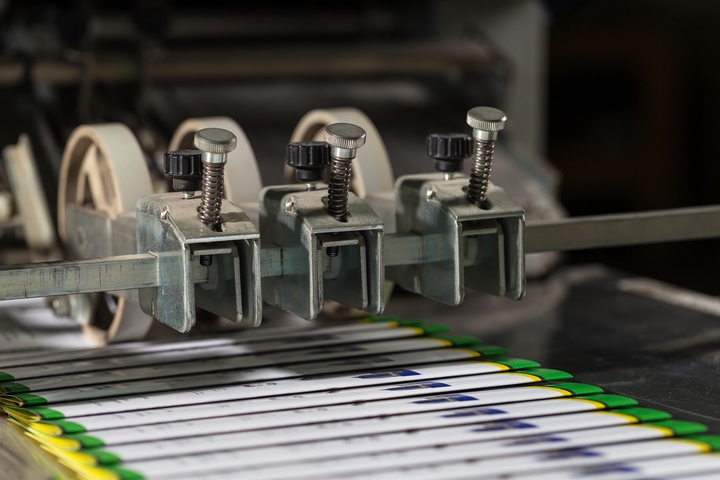

6. Strip binding machines

Offering a simple and secure format for document presentation—as the name suggests, strip binding machines run binding strips through the punched holes of the paper. Using prongs to clamp the pages of a document together, the machine then secures the strips in place using heat.

7. Saddle stitching machines

Due to the fact that these types of binding machines are quite costly and complicated to use, they are seen almost exclusively in dedicated printing companies. Saddle stitching machines punch, wire and staple through the folded edges of pages and work well with almost all book dimensions, including mini-books and oversized books.

8. Velobind binding machines

Ideal for binding legal-sized documents straight out of the box, Velobind binding machines come with different functionalities to bind books that are thick up to one inch. The method involves punching several small holes along the edge of an unbound book.

The next step is inserting the male end into the holes from the top of the book, before placing a strip with corresponding holes on the back with the tines protruding through. Used by offices the world over, these machines are also often seen in print and copy shops.